A leader in the European market since 1967, Parimix started its activity in the field of mechanical machine transfers in 1973 before turning the dosage of powders and continuous and discontinuous assays.

Parimix: The experience of dosing and mixing

In 1980 leaves the first continuous mixer, followed by mixing powder and liquid weigh feeder. 1987 saw the release of the first continuous trouble bakery in the world. In the 90s, Parimix brings to market its batch mixers (batch mixer), its shakers of dry and sticky, and Microdispenser. The 2000s were especially marked by complete facilities integrate all of our technologies for the simultaneous treatment of several products, powders and liquids. Throughout its industrial history, Parimix filed and operated numerous patents internationally recognized. The latest concerns a system for filling pasty and viscous products.

Standards and compliances

![]() Parimix studied adapting its different machines with ATEX and offers facilities that meet ATEX 21 and 22, when necessary. For application in the food industry, the materials constituting our machines are certified FDA (Food and Drug Administration). Parimix machinery and installations comply with CE standard and are provided with the corresponding certificate.

Parimix studied adapting its different machines with ATEX and offers facilities that meet ATEX 21 and 22, when necessary. For application in the food industry, the materials constituting our machines are certified FDA (Food and Drug Administration). Parimix machinery and installations comply with CE standard and are provided with the corresponding certificate.

Realization process

Every machine leaves our workshops is unique and specially tailored to the needs of our customers. Our processes go through the discussion of needs, the study 3D installation and adaptation to the customer environment, discussion of results of this study with the customer, validation and finally manufacturing. If necessary, we carry out tests with the customer’s premises or ours, in order to validate our technology and demonstrate its product quality in manufacturing.

The research department

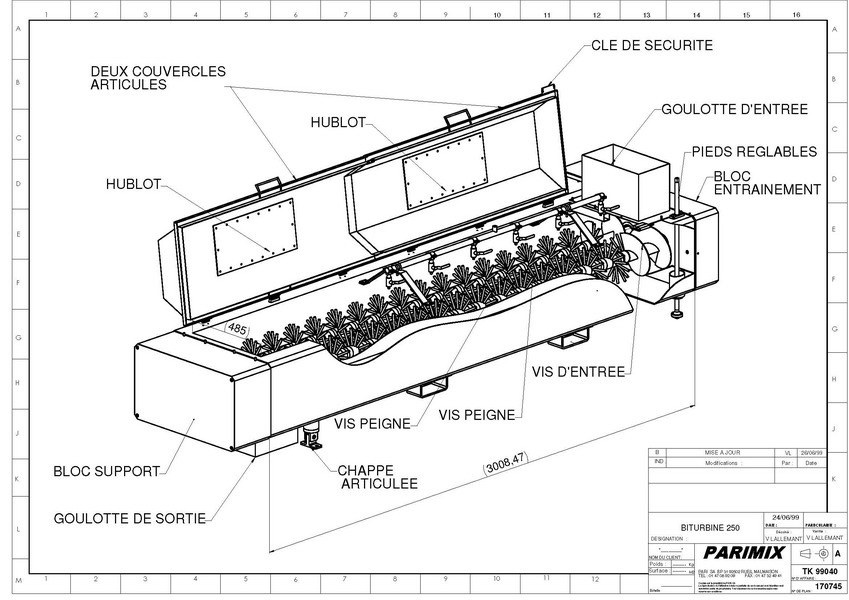

Our design department will conduct an installation with your cooperation perfectly adapted to your specifications. Forerunners in the use of IT resources and attention to the technological, we were among the first in our industry to use computer-aided design in 3D (SolidWorks), in 1997, compatible for all standard formats and particularly suitable our customized activity. Our mastery of 3D CAD enables us to manufacture more reliable studies, to better visualize the human-machine interface and facilitates installation in the customer’s plant.

The business engineers

They discuss with you the best solution for your metering and mixing projects, according to the constraints and production environment, and organize tests if necessary. They are for our clients a unique and permanent contact throughout the project. In addition, their knowledge of the sector powders and liquid allows them to act as true independent industry consultants capable of finding solutions outside Parimix in related fields dosing and mixing.

The technical service

We strive to be blameless on the quality of our service foundation of our reputation in the industry. Thus, our technical team will assist you from the study of the material until commissioning. For systems that require, we offer a commissioning service that includes a mechanical part and an electronic part. Our team of mechatronic engineers handles the electronic interface with the internal communication system, whatever it is. It was also he who takes care of the development of the machine, training, as well as compliance after commissioning. Given the simplicity of their design, our machines require little maintenance and require little spare parts. Parimix however keeps in stock the basic parts. If necessary, after-sales service intervenes in a very short time.

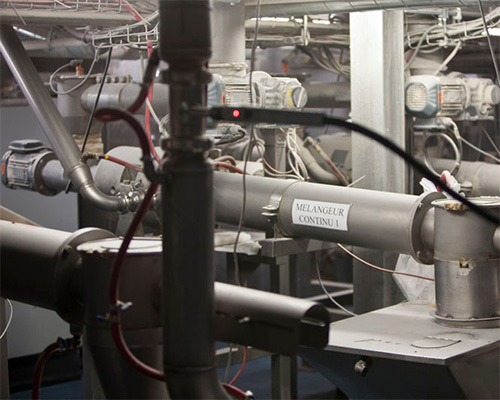

The testing station

A fleet of equipment, consisting of several dispensers, mixers and shakers, available in several sizes is available to our customers, so we tested all your products on our machines. These tests determine the appropriate type of machine to show the quality of the final product to the customer. They are also useful for evaluating equipment manufacturing parameters. Where the nature of the products does not allow to test out of the factory, or that the test should be done on the customer’s production line, we move to perform these tests.